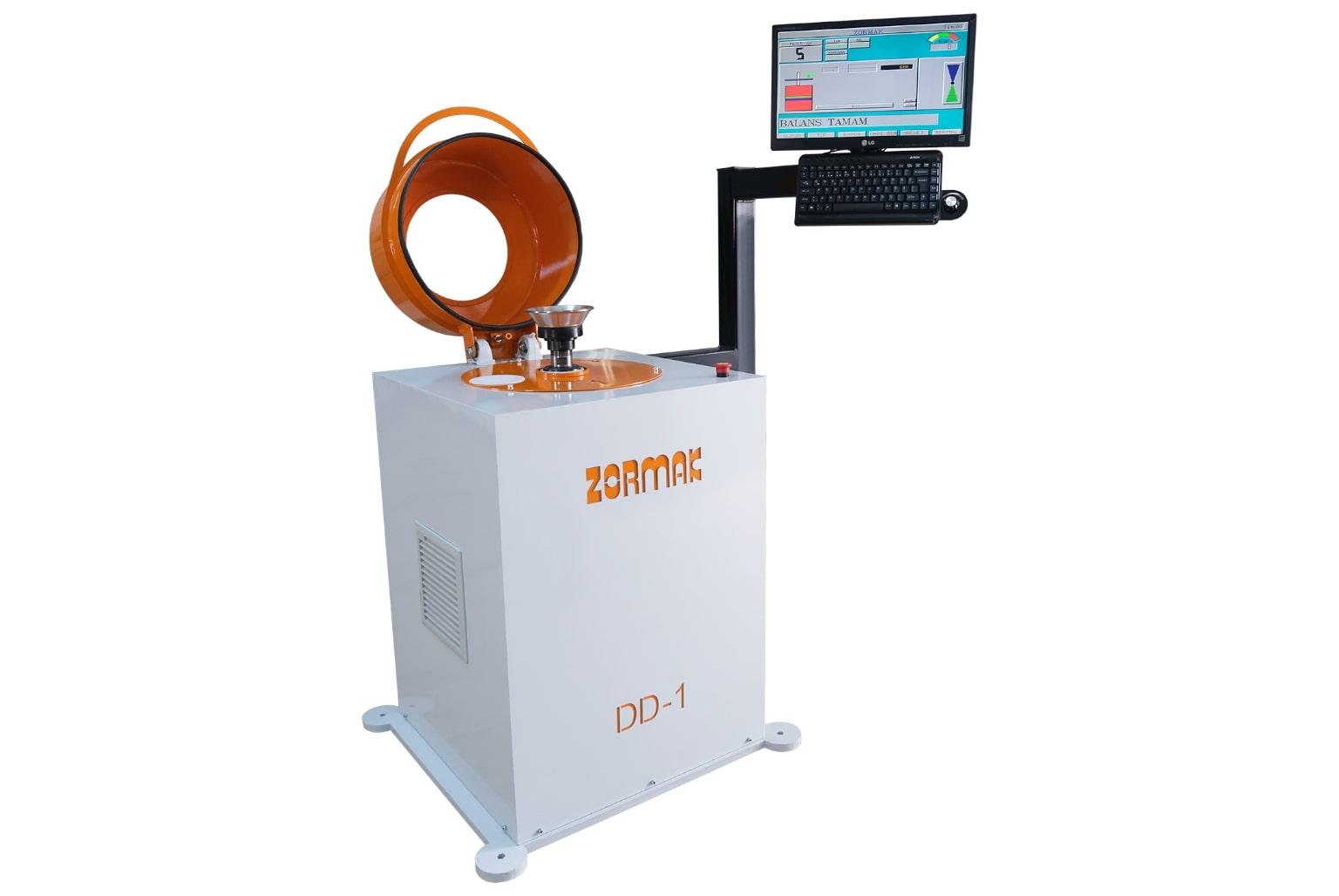

The program can optionally be utilized in both English and Turkish Languages.

* Capability of saving calibration data of 1000 different parts. To balance a different part, selecting part code for that particular part from this saved data is enough. It does not require entering any properties of the part to be balanced.

* Unequal capability of precisely compensating for the wobbling, eccentric and/or off-balance adaptor equipment, which assist in fitting various parts to be balanced. There is no need to balance those adaptors separately anymore. This way the total balancing process compensates for the off-balance shaft condition of the machine itself as well.

* Screen monitor display shows in exact values of balancing weights in grams. Previously weighed balancing weights can be used. This practical feature makes the balancing process very easy and quick.

* Practical capability of selecting addition or removal (of balancing weights) method depending of the nature of the part to be balanced, i.e. drive shafts require adding balancing weights, whereas engine crankshafts need drilling lightening holes to remove weight wherever required.

* The removal method, here, refers to removing material by drilling lightening holes on the part to be balanced. When removal method is used, the screen displays the required dept of the lightening hole to be drilled in millimeters in order to provide the best-balanced condition. To complete the operation, the computer inquires the operator to enter the type of the material to be drilled along with the drill bit size.

* Our Industrial balancing machines can accommodate up to four supports (transducers) and regardless of the number of the supports used (i.e. one up to four supports) for that particular measurement; the whole balancing operation can be done at only one time measurement (instead of several measurement tries). A three piece drive shaft requires four supports, with one transducer for each support, and this enables the computer to display up to four different balance points to satisfy the balance requirement in such precise details as balance positions and values, in only one measurement trial.

* The capability of balancing in gr-mm measurement unit. This feature is quite practical since it provides the operator with the freedom of selecting the most suitable (or reachable) radius position for drilling the lightening hole.

* The machine assists the operator by means of our worldwide unique self-conditioned on-board “Voice Instruction” feature which lets his hands remain on-the-job, as he listen the instructions to learn what to do next. This feature makes the operations so easy that literally even a novice or inexperienced person can do the balancing job very easily and with the most successful results. The voice instructions can be turned on and off as desired by the operator.

* The machine has on board capability of controlling motor and support (transducer) sensor connections. Warning phrases are displayed when a disconnected, malfunctioning or etc. situation is sensed.

* The language of operation can be selected. The standard languages readily installed are Turkish and English whereas with any large order other languages can be installed depending on the requirements of the country.

* The electric drive motor has rpm control capability. This selected rpm value can be viewed simultaneously on the screen.

* The printer can produce balance output reports one by one or in a serial manner (especially suitable for serial production lines) one by one reports contain balance position and balance weight value graphics. Serial reports, on the other hand, print only pre-balancing and post balancing values (stating and finishing gram values).

* Our machines are guaranteed for one year. Malfunctions resulting from abusive operations are not covered by the guarantee terms.

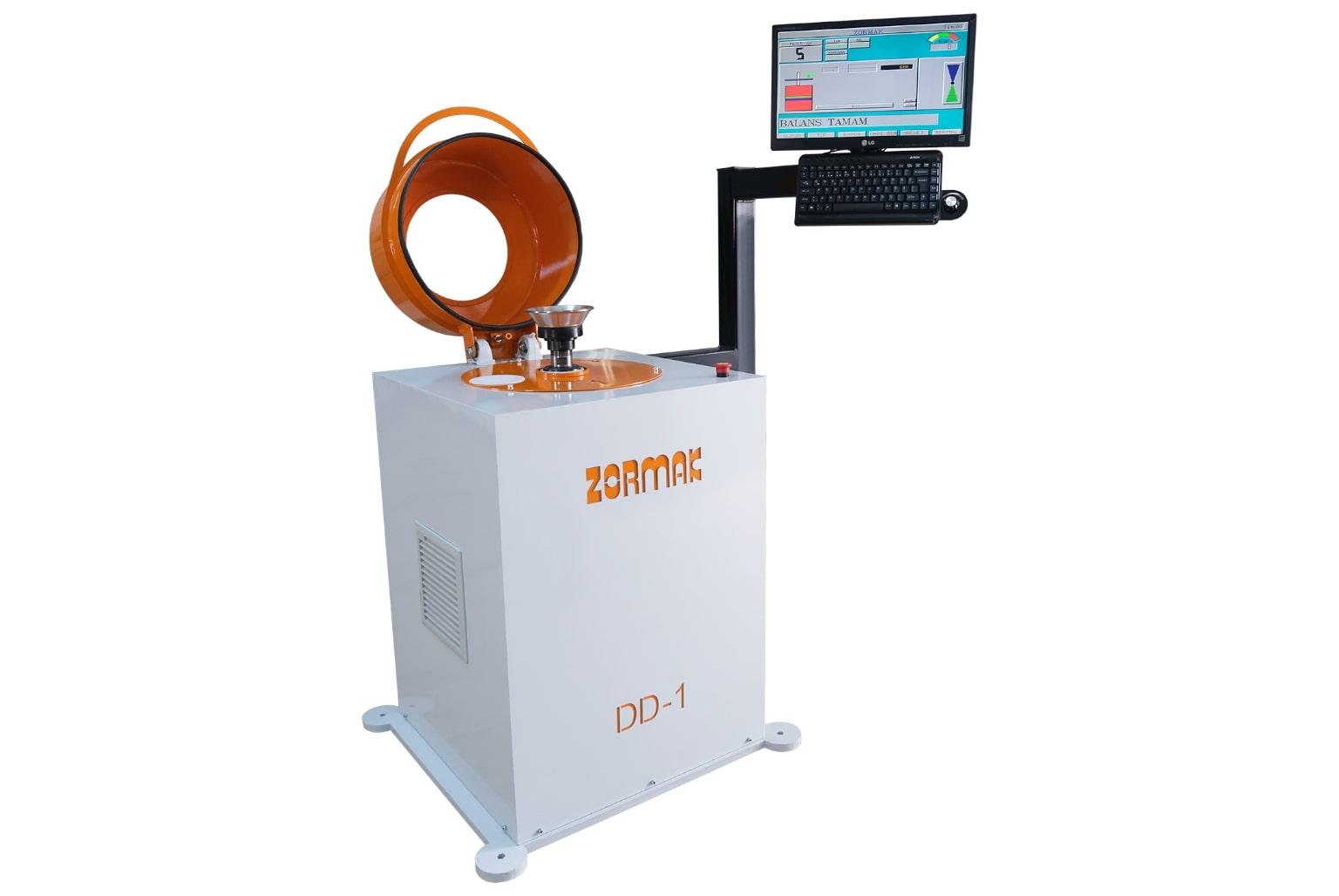

The program can optionally be utilized in both English and Turkish Languages.

* Capability of saving calibration data of 1000 different parts. To balance a different part, selecting part code for that particular part from this saved data is enough. It does not require entering any properties of the part to be balanced.

* Unequal capability of precisely compensating for the wobbling, eccentric and/or off-balance adaptor equipment, which assist in fitting various parts to be balanced. There is no need to balance those adaptors separately anymore. This way the total balancing process compensates for the off-balance shaft condition of the machine itself as well.

* Screen monitor display shows in exact values of balancing weights in grams. Previously weighed balancing weights can be used. This practical feature makes the balancing process very easy and quick.

* Practical capability of selecting addition or removal (of balancing weights) method depending of the nature of the part to be balanced, i.e. drive shafts require adding balancing weights, whereas engine crankshafts need drilling lightening holes to remove weight wherever required.

* The removal method, here, refers to removing material by drilling lightening holes on the part to be balanced. When removal method is used, the screen displays the required dept of the lightening hole to be drilled in millimeters in order to provide the best-balanced condition. To complete the operation, the computer inquires the operator to enter the type of the material to be drilled along with the drill bit size.

* Our Industrial balancing machines can accommodate up to four supports (transducers) and regardless of the number of the supports used (i.e. one up to four supports) for that particular measurement; the whole balancing operation can be done at only one time measurement (instead of several measurement tries). A three piece drive shaft requires four supports, with one transducer for each support, and this enables the computer to display up to four different balance points to satisfy the balance requirement in such precise details as balance positions and values, in only one measurement trial.

* The capability of balancing in gr-mm measurement unit. This feature is quite practical since it provides the operator with the freedom of selecting the most suitable (or reachable) radius position for drilling the lightening hole.

* The machine assists the operator by means of our worldwide unique self-conditioned on-board “Voice Instruction” feature which lets his hands remain on-the-job, as he listen the instructions to learn what to do next. This feature makes the operations so easy that literally even a novice or inexperienced person can do the balancing job very easily and with the most successful results. The voice instructions can be turned on and off as desired by the operator.

* The machine has on board capability of controlling motor and support (transducer) sensor connections. Warning phrases are displayed when a disconnected, malfunctioning or etc. situation is sensed.

* The language of operation can be selected. The standard languages readily installed are Turkish and English whereas with any large order other languages can be installed depending on the requirements of the country.

* The electric drive motor has rpm control capability. This selected rpm value can be viewed simultaneously on the screen.

* The printer can produce balance output reports one by one or in a serial manner (especially suitable for serial production lines) one by one reports contain balance position and balance weight value graphics. Serial reports, on the other hand, print only pre-balancing and post balancing values (stating and finishing gram values).

* Our machines are guaranteed for one year. Malfunctions resulting from abusive operations are not covered by the guarantee terms.

| Domestic Sales: | marketing@zormak.com.tr |

| Overseas Sales: | exports@zormak.com.tr |

| General: | management@zormak.com.tr |

| Technical Service: | service@zormak.com.tr |

| Accounting: | accounts@zormak.com.tr |